Pyroform HP is an exclusive material developed by Rex Materials for use in billet, rolling slab, and sheet casting tables. It is also a key material used in Metal Delivery Systems for certain flow rates.

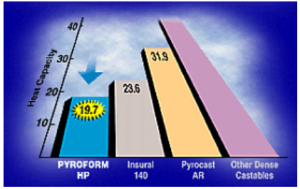

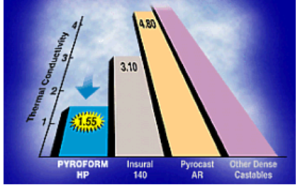

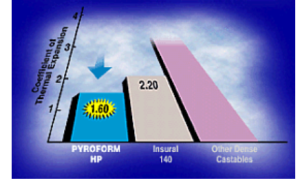

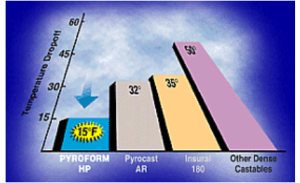

Pyroform HP has a unique combination of thermal insulating properties and durability.

The physical properties of Pyroform HP offer important ADVANTAGES:

With years of proven performance, Pyroform HP is the refractory material preferred by Wagstaff for use in their billet and rolling casting systems.

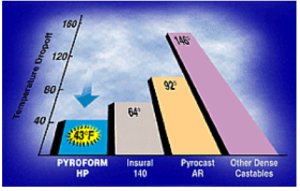

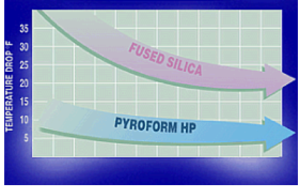

Pyroform HP has significantly lower conductive heat losses compared to both fused silica and high density castable materials. Because Pyroform HP has an extremely low thermal mass, it also takes much less energy out of the metal at the start of the cast. Together, these properties can achieve the following:

Wagstaff Table Top Refractory