Introducing AlkeGel

The Next Generation of Low Dust Aerogel Insulation for Hot and Cold Applications

Alkegen introduces a new portfolio of ultra-low-dust aerogel insulating technology materials engineered for industrial environments. These fiber-enhanced aerogels offer advantages in their improved product handleability, fire resistance and acoustical performance.

Compared to traditional aerogel blankets, Alkegen’s aerogel technology has 80% less dust and can be installed up to 20% faster. AlkeGel offers excellent handleability; it is easy to cut, lightweight, and gets the job done without the expensive PPE that traditional aerogels require.

General Benefits of AlkeGel

Extremely Low Thermal Conductivity

Flexible

Low Dust

Thermal Shock Resistance

Hydrophobic

Easy to Cut

Aerogel Comparison

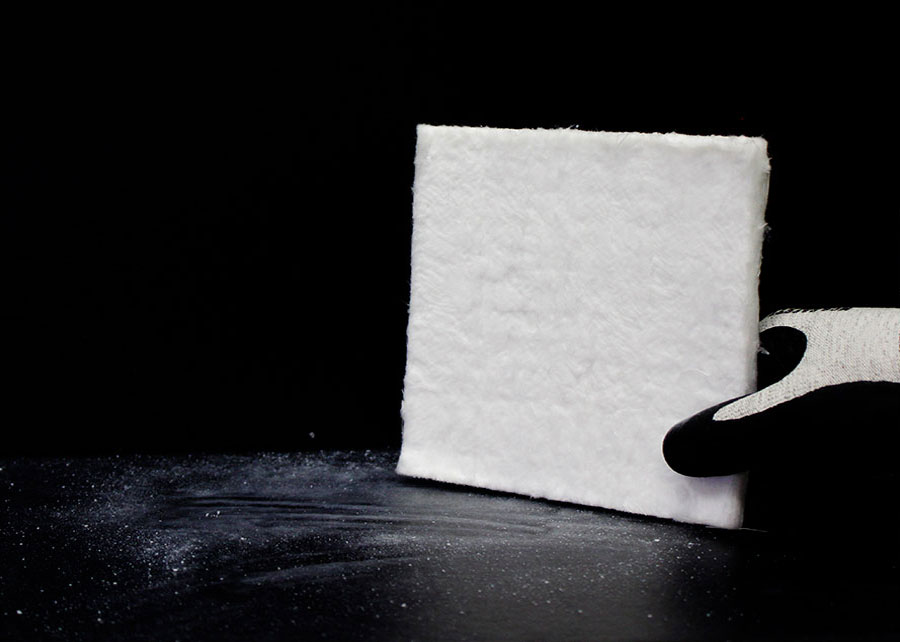

Excessive dust

Traditional Aerogel

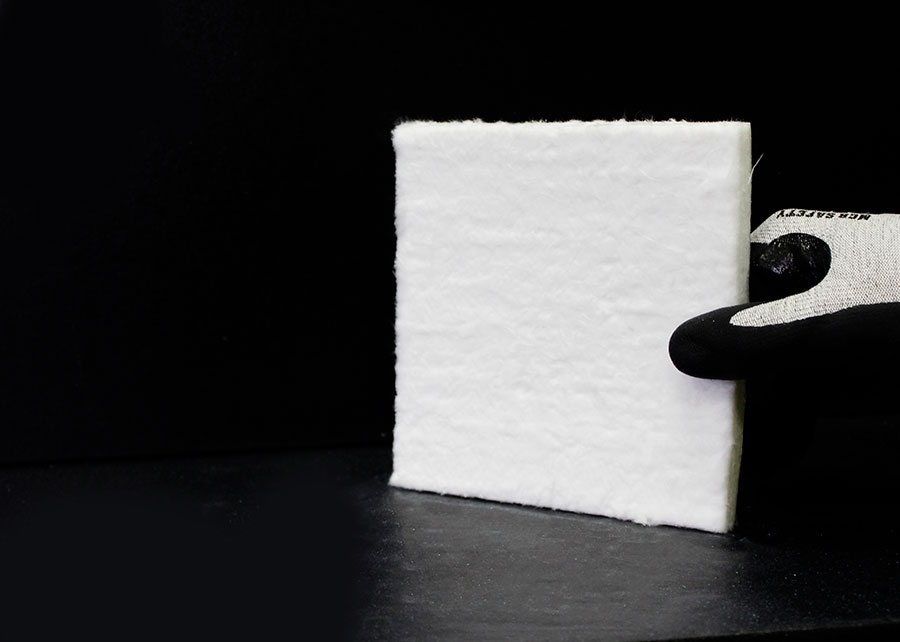

Little to no dust

AlkeGel

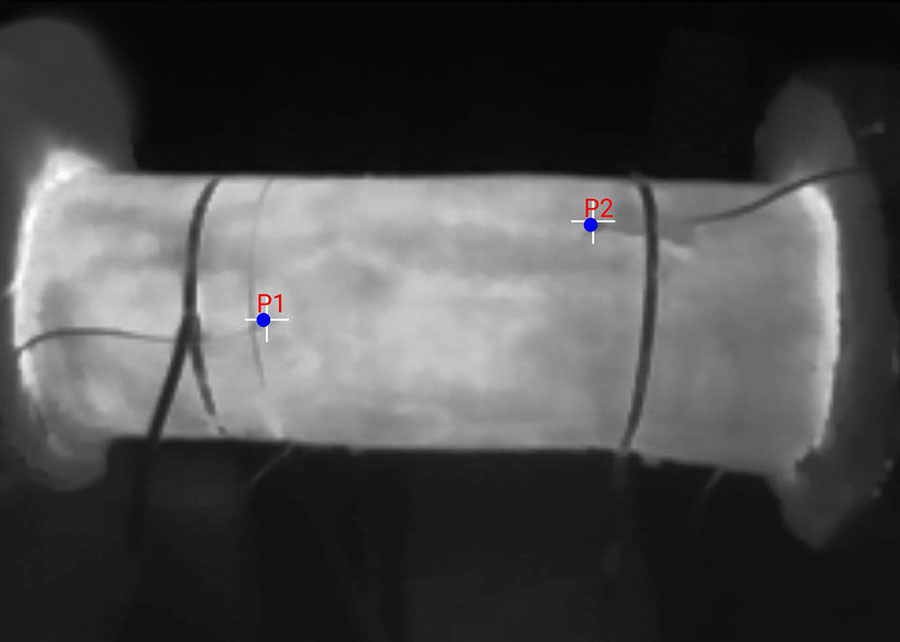

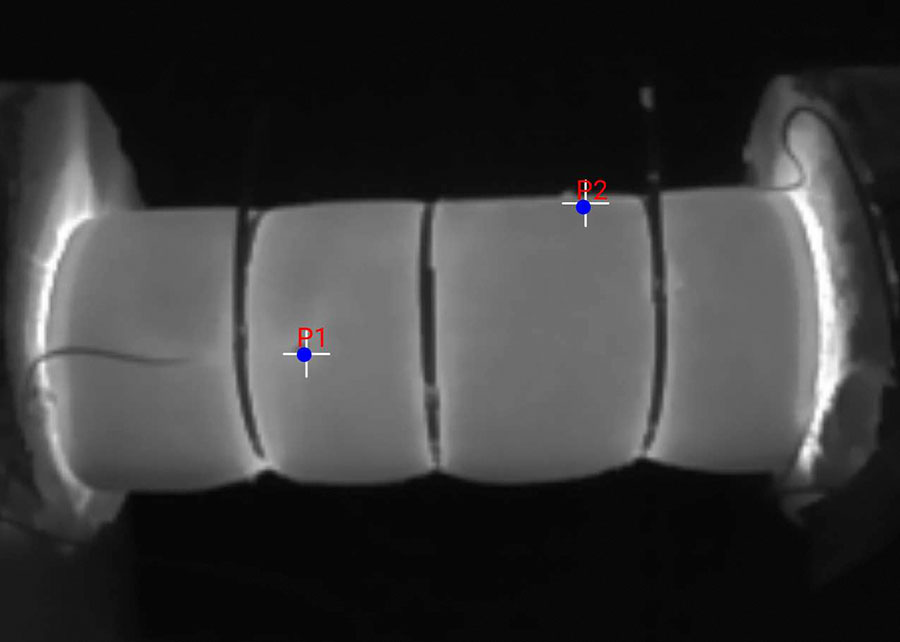

“Hot spots” due to non-uniform aerogel distribution

Traditional Aerogel

Thermal images demonstrate uniform heat flow through AlkeGel

AlkeGel

AlkeGel Ember is part of our industrial portfolio of ultra-lightweight aerogel insulating materials specifically designed for moderate-high temperature applications. These fiber-enhanced aerogels offer advantages in their improved product handleability, fire resistance and acoustical performance. AlkeGel Ember is engineered for high temperature service and to minimize the impact of Corrosion Under Insulation (CUI) on piping and large process vessels, reducing maintenance budgets and the risk of catastrophic failure.

Key Characteristics

- ASTM C1728 Compliant, Type V, Grade 1A

- 80% less dusty than traditional aerogel blankets

- Available in 5 & 10mm thicknesses

- ASTM C1763 Water absorption by immersion < 8% after heating to 316°C

Advantages of AlkeGel Ember

- 80% less dusty than traditional aerogels

- Extremely easy to cut and handle

- Superior material uniformity

- Superior heat flow uniformity

- Fiber-enhanced aerogel containing high temperature insulating wool

Typical Industries & Applications

Petrochemical & Refining

- Heat Trace / Steam Trace

- Delayed Coking

- Cracking

- Reforming

Liquified Natural Gas (LNG)

- Piping

- Terminal Storage

- Trailers, Cars, Ships

Power Generation

- Piping

AlkeGel Fyre is a fiber-enhanced aerogel blanket that provides excellent passive fire protection and thermal insulation for high temperature industrial applications. AlkeGel Fyre meets rigorous Jet Fire testing and ASTM fire resistance requirements. It protects industrial piping from CUF (corrosion under fireproofing), and easily installs with low dust performance.

AlkeGel Fyre meets the European regulatory requirement 1272/2008 (formerly European Commission Directive 97/69/EC) and does not require any special health hazard labeling.

Key Characteristics

- ASTM C1728 Compliant

- 80% less dusty that other aerogel blankets

- Available 5mm & 10mm Thicknesses

- ISO 22899 J120 Jet Fire Protection – 120 Minutes

- ASTM C1763 Water absorption by immersion 8% after heating to 316C

Advantages of AlkeGel Fyre

- 80% less dusty than traditional aerogels

- Extremely easy to cut and handle

- Superior material uniformity

- Superior heat flow uniformity

- Fiber-enhanced aerogel containing high temperature insulating wool

Typical Industries & Applications

Petrochemical & Refining

- Heat Trace / Steam Trace

- Delayed Coking

- Cracking

- Reforming

- Jacketing/Removable Covers

Liquified Natural Gas (LNG)

- Piping

- Terminal Storage

- Trailers, Cars, Ships

Power Generation

- Piping

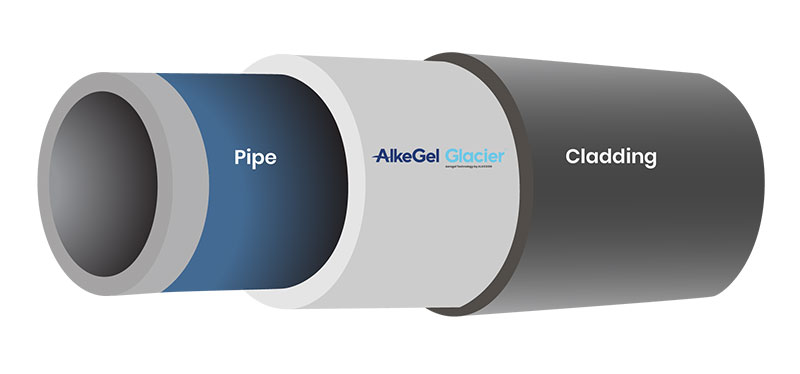

AlkeGel Glacier has been developed primarily for the LNG industry and is engineered to minimize heat transfer and liquid boil-off in cryogenic applications. Specified for use on small and large bore pipe, as well as large process vessels, AlkeGel Glacier has a zero-permeability integral vapor barrier that meets LNG requirements. Compared to traditional aerogel blankets Alkegen’s aerogel technology has 80% less dust and can be installed up to 20% faster. AlkeGel Glacier helps improve energy efficiency, and lower greenhouse gas emissions. It also protects assets from fire, ice, mechanical damage, and corrosion under insulation (CUI).

Key Characteristics

- ASTM C1728 Compliant, Type IV, Grade 1A

- 80% less dusty than traditional aerogel blankets

- Available in 5mm & 10mm thicknesses

- ISO 22899 J60 Jet Fire Protection

Advantages of AlkeGel Glacier

- 80% less dusty than traditional aerogels

- Easy to cut and handle

- Lightweight

- Superior heat flow uniformity

Typical Industries & Applications

Liquified Natural Gas (LNG) and Other Cryogenic Applications

- Terminal Pipelines

- Liquification & Regasification Installations

- Marine LNG Fuel Tanks

- Storage Vessels

Aerogel Safety

Learn how AlkeGel aerogel insulation blankets can provide advanced safety solutions for industrial applications.

Our Latest Article is Featured in LNG Magazine

AlkeGel Glacier: The Next Generation of Aerogel for Cryogenic Applications

Harry Walkoff, President, H.R. Walkoff LLC, Technical Insulation Consultant, explains Alkegen’s evolution of aerogel blankets and the development of a new product for LNG applications.

Our Latest Article is Featured in LNG Magazine