Welcome

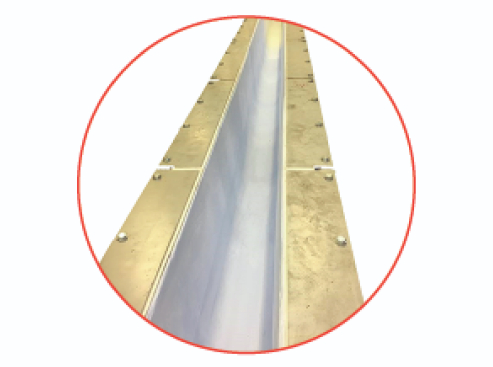

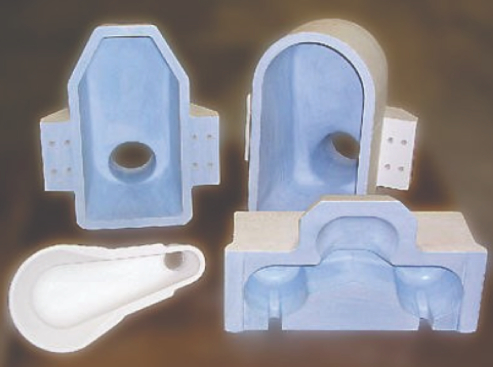

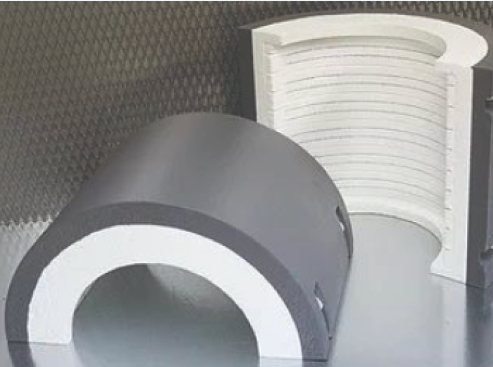

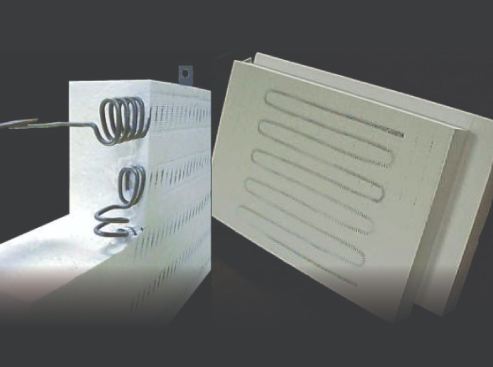

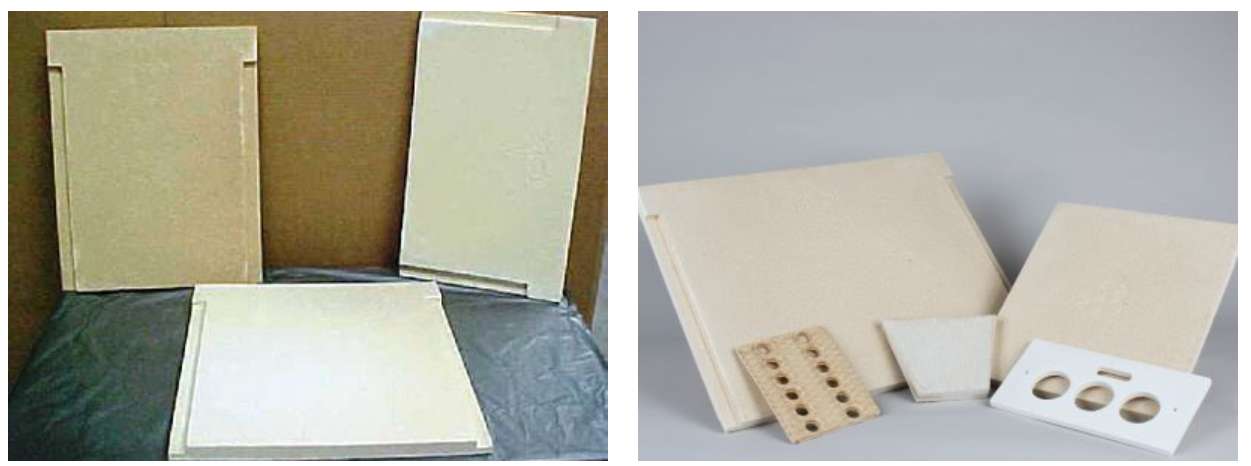

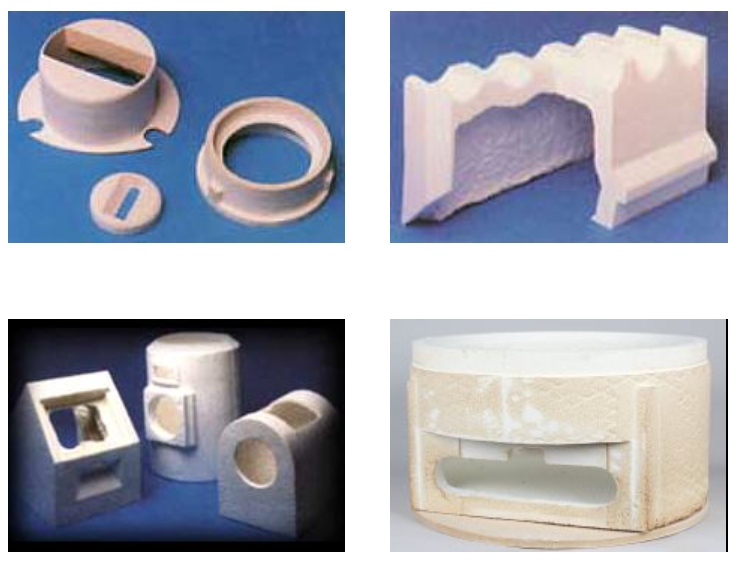

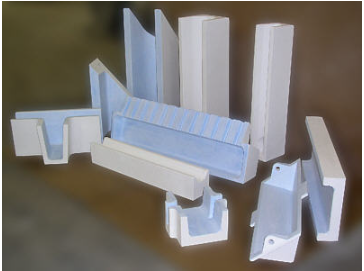

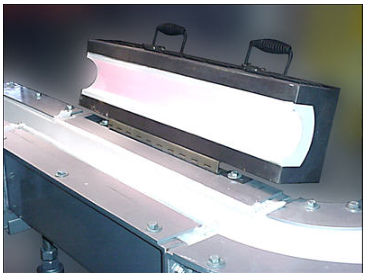

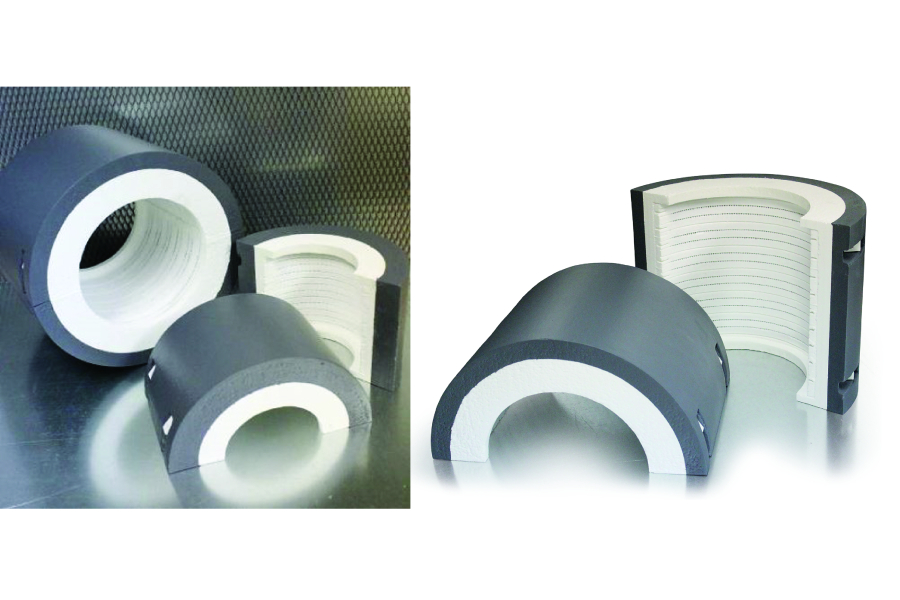

Rex Materials Group has emerged as a world leader in helping our customers solve their heat containment problems. We specialize in developing and delivering products that solve specific customer needs utilizing our custom engineered high-temperature material systems and refractory products. Our materials include PYROLITE® vacuum formed ceramic fiber, FUSiO2N™ high purity fused silica, and Pyroform HP™ insulating refractory. We also specialize in ceramic fiber heating elements for many applications. Rex Materials Group has two manufacturing facilities each with a tooling and prototype center. We have a team of engineers, designers and material scientists ready to help you solve your heat dilemma. From high-temperature insulation to molten metal handling systems to specialty heaters, we deliver solutions.

Rex History

Rex Materials has been in business for over 50 years and now represents a family of companies specializing in solving your high-temperature needs. We have emerged today as a world leader in high-temperature refractory shapes made from our ceramic fiber and fused silica families of materials. Our success has been driven by our material technology innovations, tooling capability, applications & design engineering expertise and state of the art manufacturing capabilities. Today, with over 100 different material formulations and 1000 different applications, we are positioned to solve your high-temperature requirements. As you browse the website you will get a feel for the variety of markets, materials and products we provide.

Rex Materials uses Theory of Constraint (TOC) in combination with Lean Principles to run every aspect of our business. This allows us to deliver your product when we say we will while driving out waste and increasing productivity. Rex Materials has two production facilities, one in South Hill, Virginia and the other in Council Grove, Kansas. At our corporate headquarters in Howell, Michigan, we have a complete Tool Shop, Prototype and small volume Manufacturing Capability, a Process Development Center, R&D Laboratories, and a Design Engineering Group along with our Customer Service Center and Administration.