Alkegen Battery Solutions

Innovative Battery Technologies to Power and Protect a Wide Range of Energy Applications

For battery packs and cells that require increased performance and safety, Alkegen Battery Solutions provides the right battery technologies for your battery needs. Our revolutionary silicon fiber anode technology is bringing innovation and capability to industries that require greater energy density, faster charges, and demand longer battery life. Our unique inorganic fiber separator technology promotes greater thermal stability increasing safety as energy density increases. Our thermal runaway protections, deliver enhanced protection while still optimizing pack performance with a variety of lightweight and thin thermally and electrically insulating solutions that can be used at the cell, module or pack level.

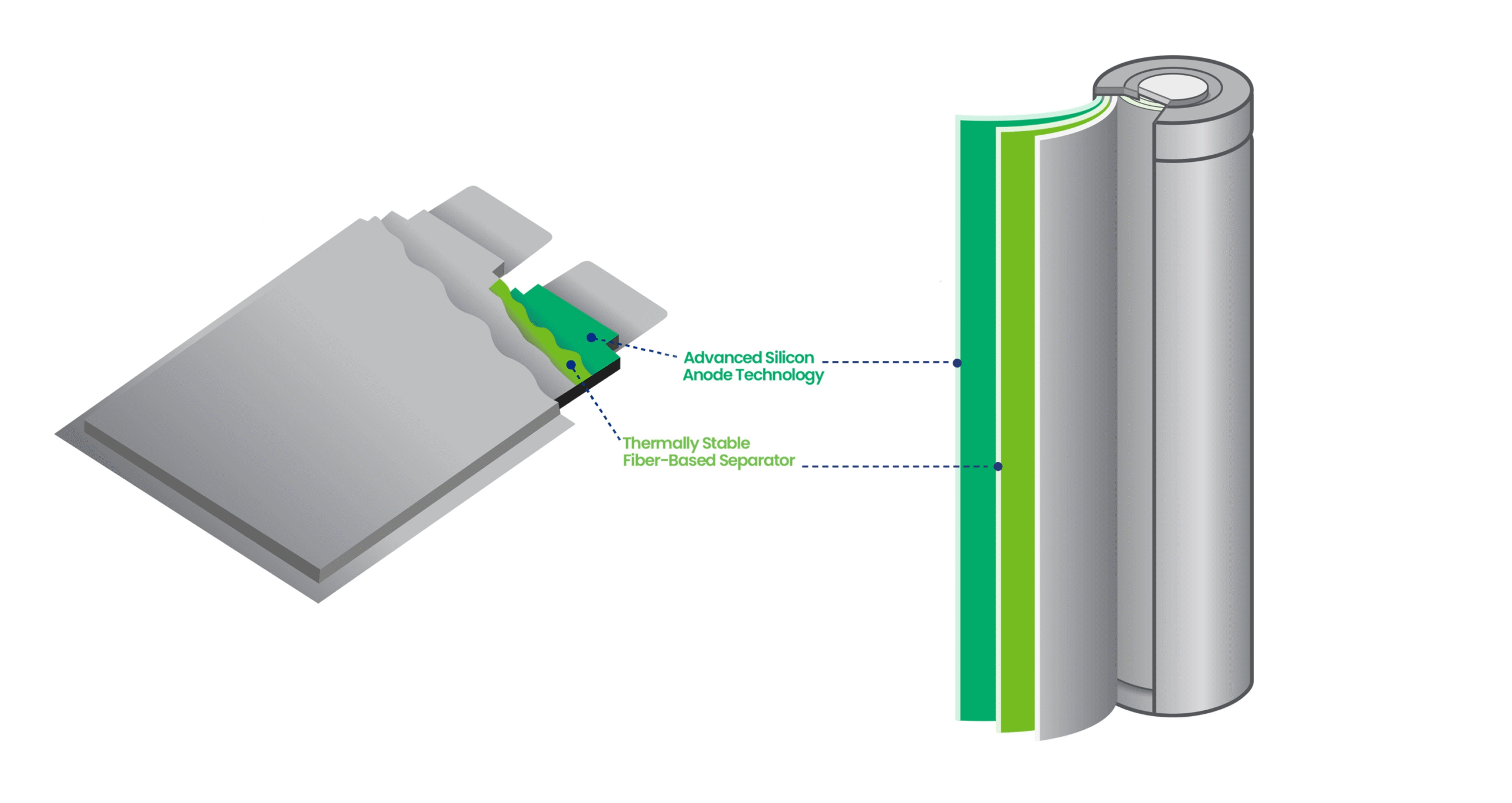

In-Cell Solutions

Advanced Silicon Anode Active Material

Scalable engineered silicon fiber anode material with unique nanoporous structure that accommodates swelling of silicon, offers high capacity, enables greater density and power output, and works well with cell manufacturers’ existing equipment.

Inorganic Fiber-Based Battery Separator

Unique microfine glass fiber-based separator technology promotes greater thermal stability and rapid ion exchange.

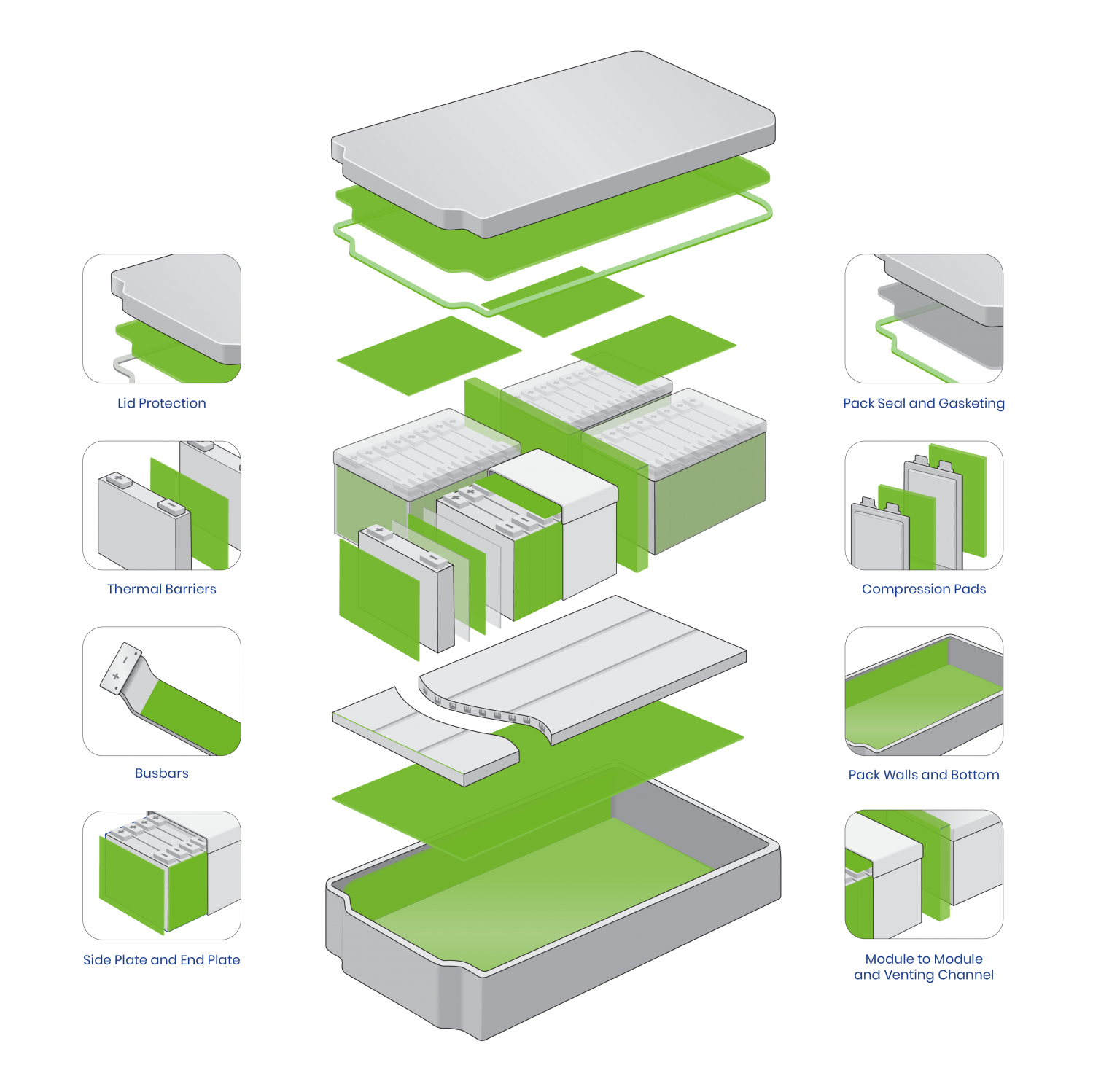

In-Pack Solutions

Lid, Module, Pack and Venting Management Protections

FyreWrap LiB Thermal Runaway Protections are a portfolio of thin, lightweight, high temperature electrically and thermally insulating technologies designed to protect various areas and functions within the pack. From ultra thin protections starting at 0.15mm to solutions that provide blast protection from cell venting flames and particulates, Alkegen has a variety of product forms and composite technologies to fit a multitude of design and performance objectives.

High Temperature Cell Spacers and Compression Pads

FyreWrap® LiB Cell Spacers are a family of high-temperature, lightweight insulating materials designed to prevent or delay thermal runaway propagation while providing consistent and predictable pressures on the face of the cells over the lifespan of the pack.

In-Cell Features + Benefits

Platform technologies allow flexible material design for different battery needs.

Proprietary and vertically integrated manufacturing processes provide supply chain safety to customers across broad applications.

Advanced silicon fiber anode technology enables higher energy density, greater power output, faster charge time and minimal swelling.

Inorganic fiber-based separator with exceptional high temperature performance offers a safer separator for high energy batteries.

In-Pack Features + Benefits

Choose from a selection of high-temperature, lightweight products to reduce thermal runaway propagation and provide mechanical, electrical, and thermal protections in the battery pack.

Derived from product expertise, and decades of proven performance, in thermal insulation, automotive, and fire protection applications.

Vertically integrated across multiple inorganic and synthetic fiber and process technology platforms.

Automotive accredited part production and bespoke solutions utilizing papers, felts, coatings, films, 3D shapes, boards, blankets and composite materials combining pressure-sensitive adhesives, mica, foams and other functional layers.

Learn more about the right battery technology for your needs

Let's ChatBattery Solutions by Industry

Alkegen’s innovative materials and technologies enhance safety and improve battery performance across a variety of industries, including e-Mobility, aerospace, energy storage systems, and portable electronics.

Battery OEMs

We provide high quality manufacturing with a vertically integrated supply chain for dependable product availability. OEMs value our cutting-edge battery innovations and partnership. We develop solutions that can be customized to individual manufacturing specifications that meet performance requirements.

Automotive

We are an experienced supplier of engineered materials to the automotive industry. Whether a current model or a next-generation vehicle platform, Alkegen’s battery solutions enable electric vehicle users to go further than ever before, providing peace of mind through increased pack range and enhanced vehicle safety during any journey.

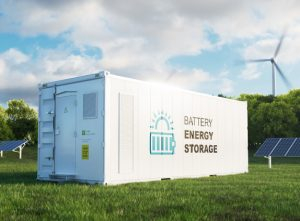

Energy Storage Systems

When you are defined by the amount of power and energy you are able to store, you need a trustworthy configuration. Use our cutting-edge battery solutions to elevate capacities and always keep the power on. We offer proven fire safety, optimal energy density, and longer battery life.

Aerospace

High power, energy dense, and easily rechargeable, Alkegen’s advanced anode and separator technologies integrated with Alkegen’s light-weight, and ultra-thin thermal runaway protections help you meet your battery performance needs in even the most extreme environments.

Power your future with our revolutionary Alkegen Battery Technologies

Connect with Us TodayTechnical Capabilities

Transforming Industries from Ideation to Production

Development

Streamline the Development Stage

Enable breakthrough solutions at an industrial scale from the beginning. The Alkegen Battery Group has you covered with proprietary know-how in materials science and process engineering.

Design

Create the Perfect Fit for Customers

Ensure form, fit, and function of products are optimized for customers with our global design team’s 3D modeling collaboration software.

Testing

Test New Parts and Products

Validate thermal, mechanical, environmental, compression, and electrochemical parts and products during development and beyond with help from our team.

Prototyping

Prove Product Functionality

Once your products are designed, the Alkegen Battery Group engineering teams will prototype them to validate functionality.

Scale

Serial Production Made Easy

Get regional support and scale-up solutions with Alkegen’s IATF-certified sites and engineering teams in North America, Europe, and the Asia-Pacific region.

Request samples or need more information?

Call the Alkegen Battery Group at 1 716 768 6472

Email us at: batterygroup@alkegen.com

Why the Alkegen Battery Group?

Working with the Alkegen Battery Group means you’ll collaborate with our global team of engineers and designers to bring custom solutions tailored to your unique application needs. With access to a full suite of technical capabilities, including more than 140 separate thermal, electrical, acoustical, analytical, and mechanical test methods that support rapid solution development, our team is dedicated to building products that meet your budget and optimize performance.