Purefrax® filter elements are vacuum formed using Alkegen’s own refractory ceramic fibers, and are manufactured from Alkaline Earth Silicate (low bio-persistent/AES) or Alumino Silicate wool (ASW).

Our unique binding system provides low levels of organic binder, enabling Purefrax® filters to retain strength and integrity when exposed to heat.

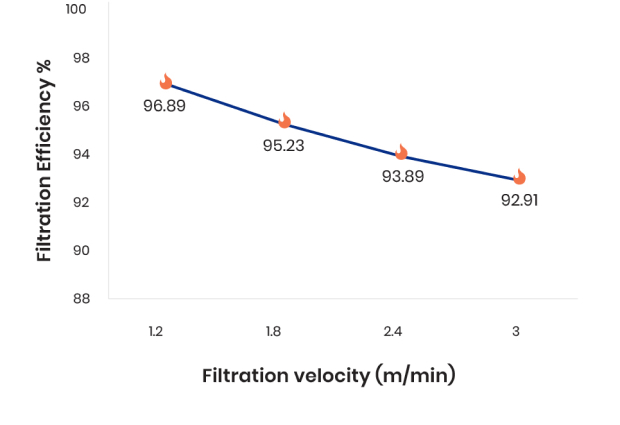

With our trusted manufacturing process, we ensure dimensional accuracy and a denser outer surface, promoting cake filtration and uniform dust deposition in addition to extra strengthening of the flange and candle base areas.

Introducing Purefrax dP, a new product offering with reduced pressure drop. Engineered for energy efficiency, our new formulation demonstrates 64% pressure drop and 6x fewer cleans compared to our standard hot gas filters, providing you with an estimated >10% operational cost savings. With higher air flow for less capital cost, Purefrax dP is the superior choice for energy efficiency.

In addition to providing high efficiency particulate filtration, Purefrax® CC filter elements incorporate a custom-designed catalytic formulation for NOx reduction.

Uniting particulate capture with toxic gas removal creates a single-step process with reduced required space, all while lowering your capital and operating costs.

Independent testing shows almost 100% NOx conversion and <5ppm ammonia slip across a wide range of applications.

With our thorough understanding of customer needs and expectations, we provide solutions that are suited to a range of industries.

Purefrax® elements are available in 1m to 4m single piece lengths and are supplied with gaskets to ensure good sealing. Contact us to learn more.

Purefrax® Product Information SheetPurefrax® CC Product Information Sheet