Energy Efficiency

By minimizing heat loss, Alkegen’s low thermal mass insulation reduces the energy required to maintain a desired temperature. This leads to lower energy consumption and contributes to furnace sustainability.

Lower operational expenses and reduce your CO2 footprint with Alkegen’s energy saving products. Our high-insulating, low thermal mass solutions can reduce fuel consumption by as much as 30%.

Read about Alkegen’s Carbowall Installation and how we helped reduce CO2 emissions by 3264 kg/day:

2030: Reduce carbon footprint by 30%

2050: Carbon-neutral

In the dynamic realm of industrial processes, the quest to reduce carbon emissions and cut down energy costs has never been more crucial. Recognizing the pivotal role of heat as a critical resource, each step towards improved furnace performance translates into not just cost savings, but a substantial decrease in carbon footprint.

When it comes to furnace efficiency, strategic solutions are available that can help to enable a world where industrial furnaces become champions of energy conservation, significantly lowering operational costs while embracing a sustainable ethos.

Steel, petrochemical and other industrial sites who depend on maintaining high temperatures for their processes, face inherent challenges. During maintenance shutdowns – where every move is strategic – products that confidently navigate the labyrinth of confined spaces and ease of installation offer advantages. Beyond addressing critical safety risks, they guarantee a secure pathway to operational excellence, minimizing downtime and advancing the pursuit of carbon neutrality.

By minimizing heat loss, Alkegen’s low thermal mass insulation reduces the energy required to maintain a desired temperature. This leads to lower energy consumption and contributes to furnace sustainability.

Our low thermal mass insulation products reduce energy costs. Minimizing heat loss requires less energy for heating as critical temperatures are maintained, resulting in significant cost savings over time.

Heat loss happens. Alkegen’s insulation solutions keep heat inside the furnace, maintaining consistent temperatures, and reducing temperature fluctuations for an efficient furnace environment.

By implementing Alkegen’s insulation products and solutions, you can reduce your carbon footprint through minimized energy consumption and improved furnace efficiency.

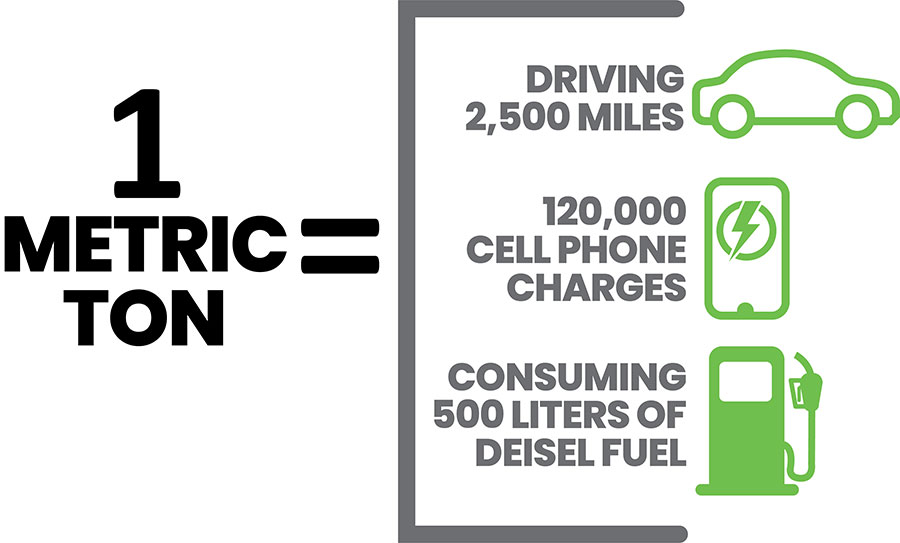

A smaller carbon footprint through Alkegen’s optimized thermal processes will reduce your energy consumption by 50 – 500 metric tons per year for small to medium-sized furnaces. You will see greater carbon reductions in larger furnaces . Replacing traditional refractory with Alkegen’s Low Thermal Mass Solutions will improve energy use, reduce emissions, and lower operational costs for a sustainable future.

Alkegen’s ceramic fiber solutions benefit every step of the steel making process, providing exceptional performance where reducing heat loss is critical. The high insulating properties of our products maintain consistent temperatures in the convection and radiant sections of the furnace, keeping heat inside with minimal heat loss. Thermal proficiency extends the life of your furnace and lowers energy consumption to minimize your CO2 footprint.

For Aluminum refractory repairs or full replacements, Thermbond solutions help you optimize production, minimize downtime, and get the most out of your refractory linings and shapes. Setting and firing times are 50% faster than traditional products – getting you back online efficiently and providing long-term performance to maximize energy reduction.

Maximizing the thermal efficiency of HPI systems requires dependable insulation products that stand up in harsh industrial processes. Alkegen’s low thermal conductivity solutions provide mechanical stability in demanding environments and extend the service life of your equipment and operation.

We engineer and develop specialized products and solutions for the Petrochemical and Refinery industries that improve efficiency by reducing energy consumption and lower CO2 emissions.

Our revolutionary fiber-based technologies improve industrial emission control, allowing factories across multiple industries to reduce their carbon footprints, meet stricter EPA standards, and enhance their ESG strategies.

Read the story behind the white paper: How one company was able to reduce energy consumption, CO2 emissions, operating costs and extend the service life of their operations with Alkegen’s Carbowall System.

This article was originally published in the May 2024 issue of Hydrocarbon Engineering magazine.

We develop insulation products and solutions that allow high-temperature applications to reduce energy consumption. Minimizing heat loss saves time, money lowers CO2 emissions to help us breathe easier, live greener and go further than ever before.

Alkegen can help you reduce your carbon footprint by 50 – 500 metric tons per year.